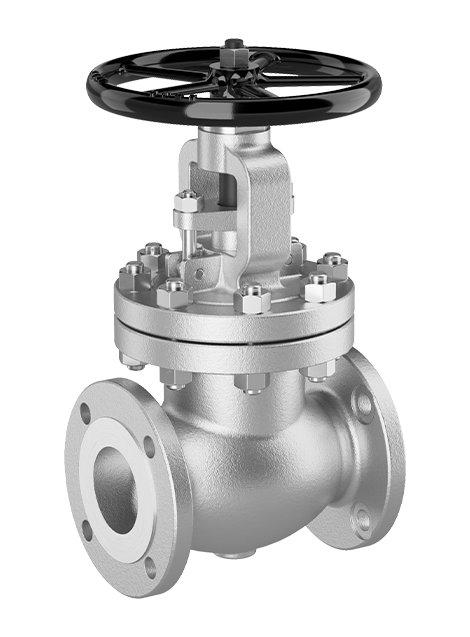

The Beaver API 600 Cast Steel Bolted Bonnet Globe Valve is suitable for throttling, shut-off,

and on/off services, provided pressure drop isn’t a critical factor when the valve is open.

It has a T-pattern design, which means the stem and disc travel perpendicular to the flow, and the seat opens proportionally to how far the disc has travelled. This gives the valve high flow resistance but also makes it prone to high pressure drop.

The valve has a conical plug disc which rotates freely on the stem at a differential angle to the seat ring. In the closed position, this provides complete shut-off and reduces the risk of the disc sticking in the body seat.

Beaver cast steel bolted bonnet globe valves are available in L31, L32, and L33 models, and exceed requirements set by API 600 standards. You can choose from three different pressure classes (Class 150, 300, and 600) to suit your requirements.

Technical specifications

Brand

Model

L32 (Class 300)

L33 (Class 600)

Size range

Class 300: DN50–400 (2–16”)

Class 600: DN50–300 (2–12”)

Pressure class

End connections

End flange: ASME B16.5

Buttweld: ASME B16.25

Technical specifications

Body, bonnet, gland flange

A352 LCC

A217 WC6

A217 WC9

A217 C5

A217 C12

A351 CF8M

Gate

A352 LCC + 316 SS

A217 WC6 + 13CR

A217 C5 + 13CR

A217 C12 + 13CR

A315 CF8M

Seat ring

A182 F11

A182 F22

A182 F5

A182 F9

A182 F316 all with Stellite

Handwheel

Stem

A182 F316

Backseat bushing, packing gland, disc nut

A276 316

Handwheel nut, gland eyebolt pin

A276 316

Bonnet bolt, gland eyebolt

A320 L7

A193 B16

A193 B8

Bonnet nut, gland adjustment nut

A194 4

A194 8

Packing

Gasket

Class 600: Soft ring joint