Predictable maintenance made easy

Wouldn't it be nice if you never had to think about slurry piping again? Smart reliability teams have escaped reactive maintenance hell and adopted a set and forget approach. No more band-aid fixes. No more emergency repairs.

Your $300M plant shouldn't go down because of one spool

And you shouldn’t be constantly bogged down by something as simple as slurry piping. SlurryIQ allows you to make long term improvements to whole sections of piping. It’s a hands-off process that boosts availability and throughput in your plant.

Redesigned. Optimised. Done for you.

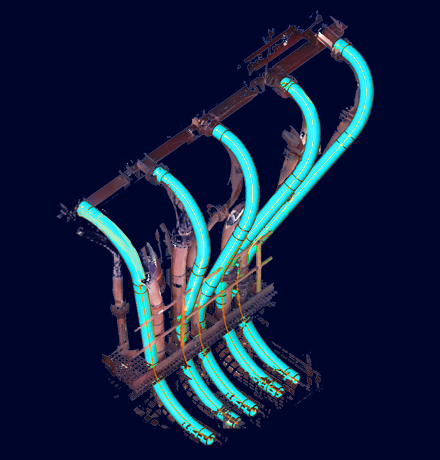

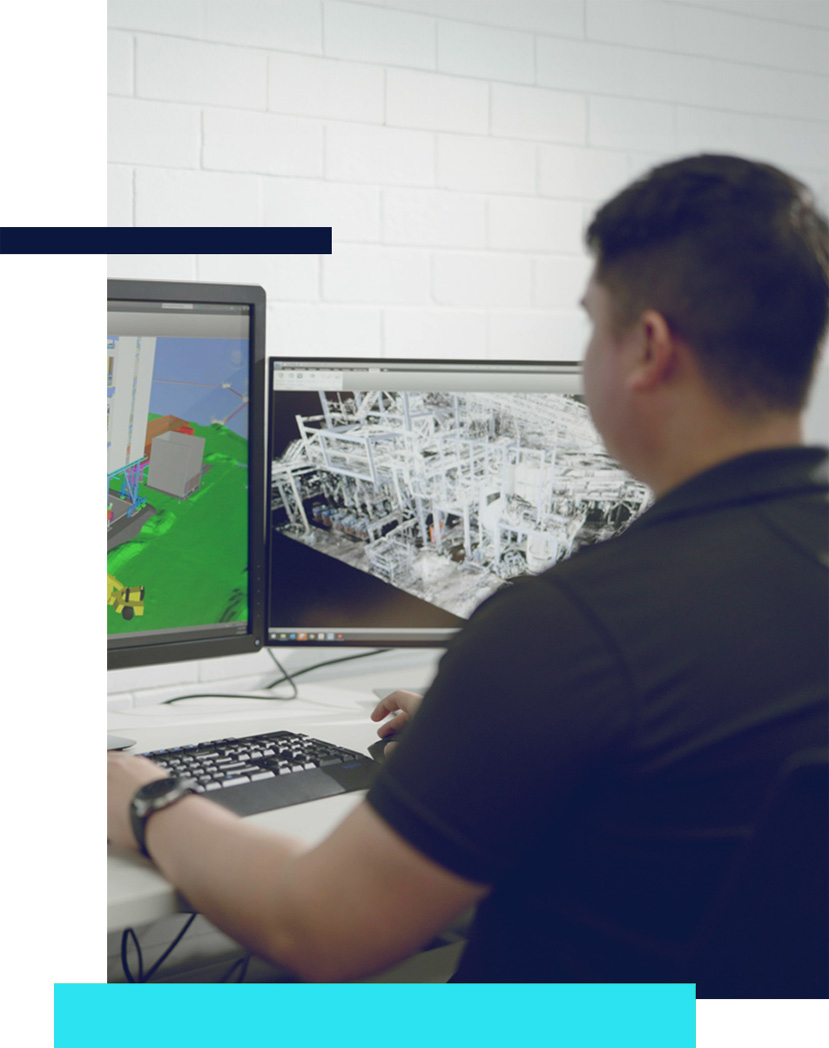

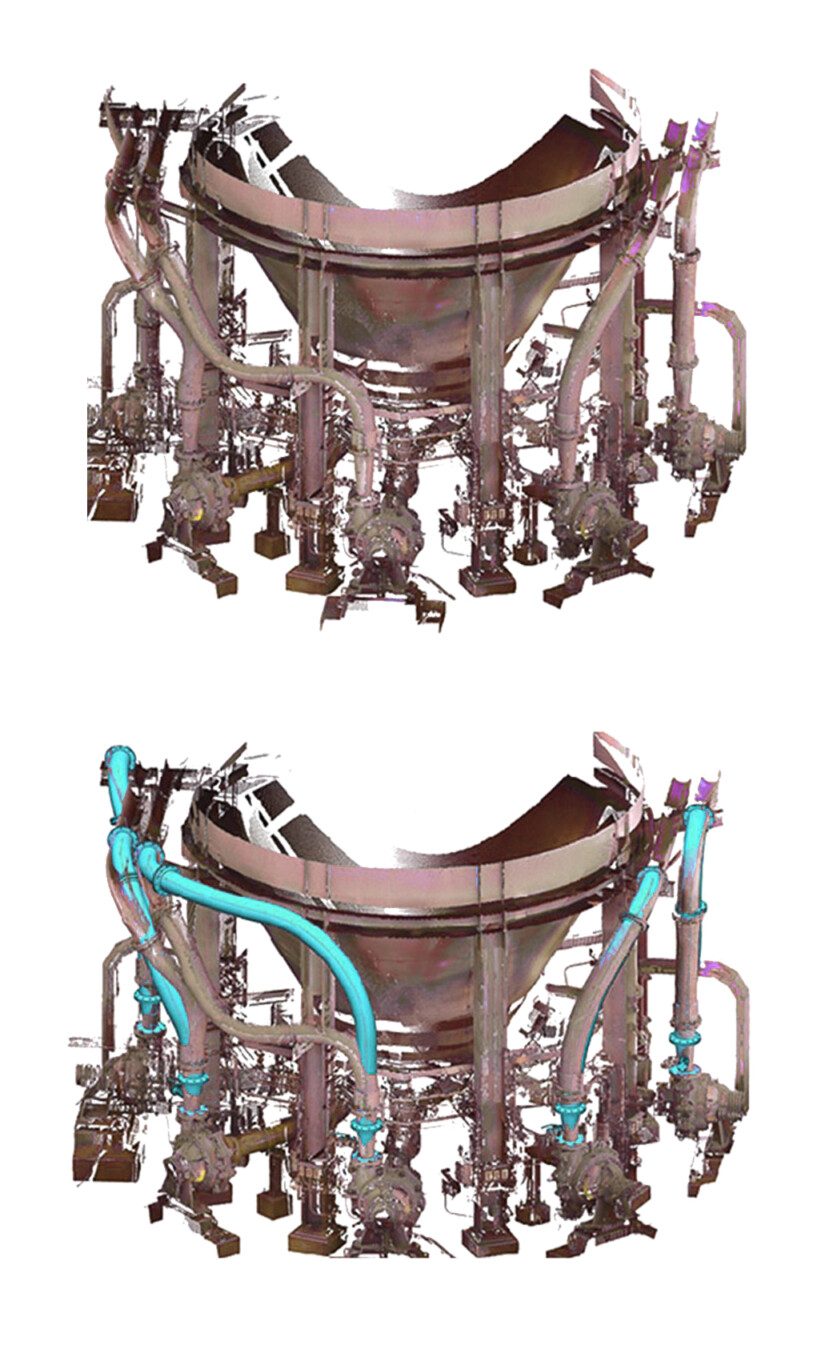

No drawings? No problem. There's no need to get out the measuring tape. We precisely scan your piping then optimise the layout and design for better wear performance.

10x Wear Life Improvement How Roy Hill took control of piping maintenance

Address the root cause of your piping failures

Repeat piping failures are typically caused by poorly designed, dated slurry piping technology. 100-year-old rubber lining just isn't suitable for the relentless wear and tear of a modern process plant.

We’ll help you identify critical areas for improvement and recommend the most suitable piping technology. So you don't have to think about slurry piping any more.

Redesign for set and forget

Without accurate drawings, it's difficult and time consuming for you to measure spools then design improvements to a whole slurry piping line.

Take an entire line, or your entire plant, and have it scanned, modelled, and redesigned to eliminate unplanned failures. We’ll optimise the design to reduce sharp bends, remove hot spots and improve slurry flow.

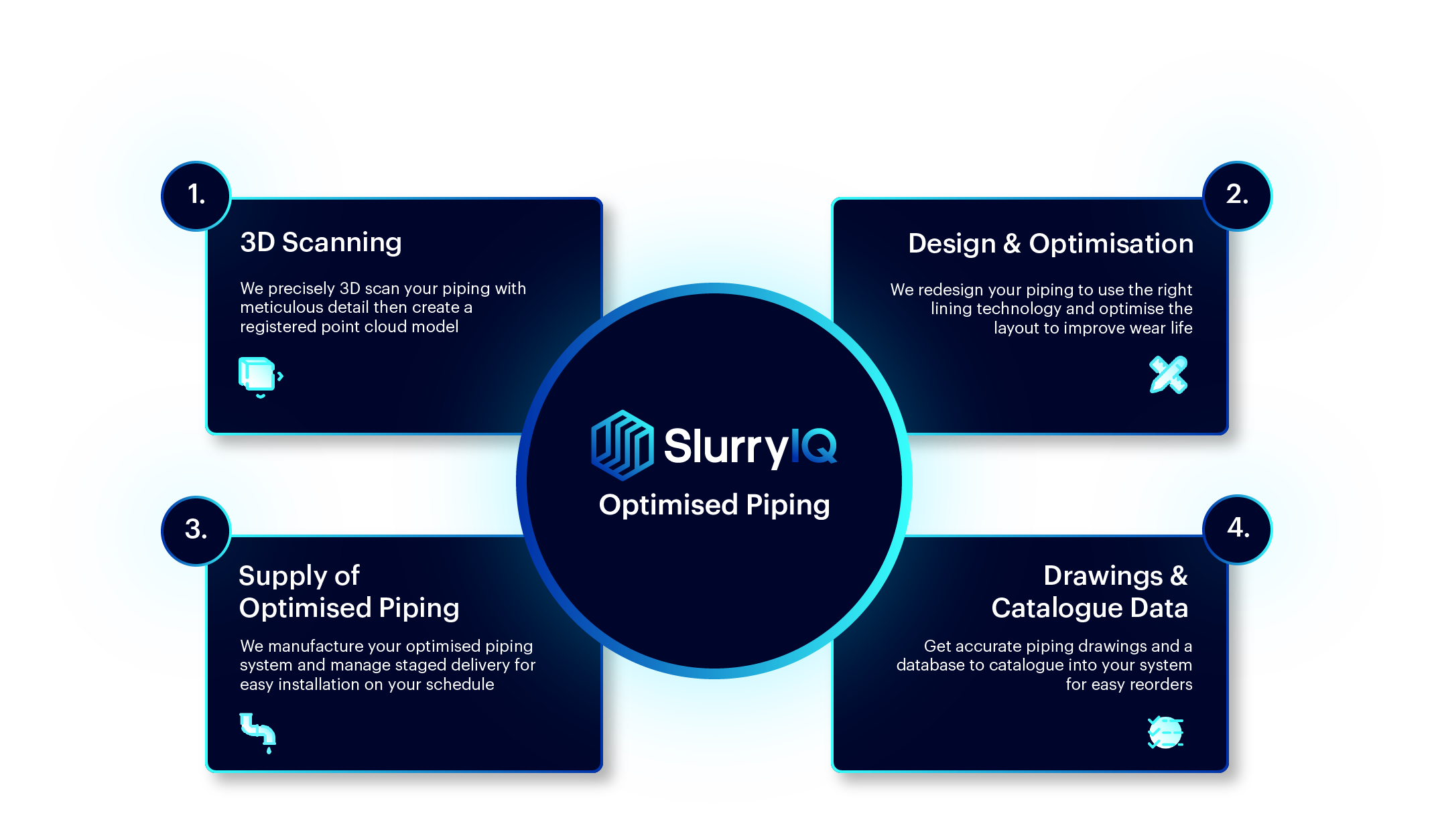

How it works: the SlurryIQ process

SlurryIQ customers include:

Want to learn more about SlurryIQ?

Find out if SlurryIQ is right for your site. Talk to a piping specialist to find out more.