Pinch Valves Products

How we help you choose the right valves:

FAQ

Can you supply pinch valve packages for large projects?

We can provide any number of valves, from small quantities through to large valve packages. Our in-house capabilities include designing, assembling, and testing large valve automation projects. We supply and distribute a variety of valves around the world.

I need a fast turnaround time, can you help?

Yes, let us know when you need your products by and we’ll do our best to supply them by your deadline. Lead times do vary depending on the exact valves you require. Contact us with your requirements and we will do our best to expedite delivery.

Learn more

What is a pinch valve and what is it used for?

A pinch valve is a component of piping systems used to isolate and regulate flow of abrasive liquids, viscous liquids and liquids containing solids. Pinch valves are commonly used in mineral processing plants and other industrial applications. Pinch valves are very different valves compared to a ball, gate and butterfly valve.

How do pinch valves work?

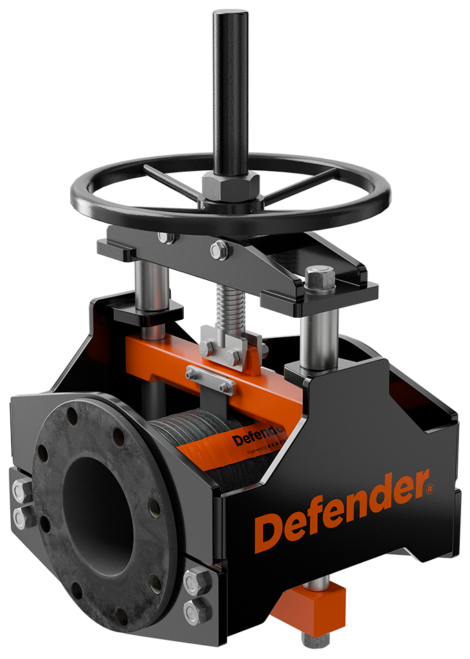

Pinch valves consist of a housing which has an internal sleeve that can be actuated pneumatically, electrically, manually, and hydraulically. When the sleeve is squeezed together it restricts the flow of liquid to create a tight seal. When it is in a fully open position it does not restrict the flow and enable liquids containing solids to pass freely.

What are advantages of a pinch valve?

One of the main advantages of a pinch valve is that they are one of few valves that can be used to control / modulate fluids in abrasive surface applications. They have a relatively low cost of ownership, no mechanical parts come into contact with the media, the sleeve can be replaced easily, require little maintenance, and are simple to actuate. They create an excellent isolation and when fully open and create very little turbulence or friction.

What are disadvantages of a pinch valve?

Pinch valves are not suited to high temperature liquids due to the sleeve’s properties. They are also not suited to vacuum pressure situations as any suction can cause the sleeve to collapse.

How do you actuate a pinch valve?

Pinch valves can be actuated manually (handwheel or gearbox), pneumatically (air pressure), electrically or hydraulically.

Can you use a pinch valve for abrasive slurry?

Yes, pinch valves are well suited to abrasive and viscous liquids containing solids.

What are the fittings of a pinch valve?

The main components of a pinch valve include the sleeve, body, closure mechanism and actuator.

What size and pressure class are your pinch valves?

Our Beaver Process Equipment pinch valve comes in DN25-600. If you need a size outside of this contact our team. As standard, our pinch valves have a pressure class of 10 bar. Contact us for a 0-30 bar option.