Mining Hose Products

How we help you choose the right hose:

Get the right mining hose for your plant

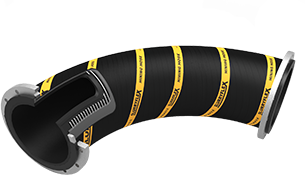

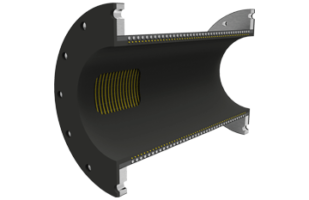

After years of research and development, we've created Slurryflex. The world's most flexible and durable mining hose.

To help you choose the right hose for your plant, we give you practical advice based on years of experience. Then, every hose is custom made for you by our highly-trained, skilled craftsmen.

Australian made quality

With the biggest slurry hose manufacturing facility in Australia, we can handle the largest projects. You can count on quick turnaround times, a secure local supply chain, and ISO 9001-certified quality.

Whether you need large sizes, long lengths, high pressure hose or a custom shape, we can build a hose to suit. Dealing with extreme temperatures, acids, hydrocarbons, or other severe applications? We'll help you find a solution.

Less maintenance and plant downtime

Tired of pipe spools and hose bends failing every six weeks? Independent testing shows that no other hose is as durable as Slurryflex.

Longer lasting hose gives you more uptime and a more efficient plant. You'll spend less time bandaging leaking pipes, and more time working on more important parts of the plant.

Flexible hose that fits right the first time

We know it's frustrating when replacement pipe spools just won't fit. Rubber mining hose is flexible, so it's easier to install. This gives you less risk and less wasted time during shutdowns.

To make sure your hose fits perfectly, we build it to match the internal diameter and end connections of your existing pipework. You can even choose from pre-formed bends, Y-pieces and custom configurations.

FAQ

Where are your mining hoses manufactured?

We manufacture all Slurryflex hoses right here in Australia. In fact, we have the biggest hose manufacturing facility in Australia, so we can handle projects of any size.

Is your hose suitable to high temperature and other unique applications?

Yes, every Slurryflex hose is custom designed and built to suit your application. Talk to us about what you need to achieve and we’ll help you find the right solution.

Is your hose ISO 9001 certified?

Yes. As one of the few mining hose manufacturers with ISO 9001 accreditation, we follow a rigorous quality management process. This ensures you get a mining hose that is consistently reliable and made to the highest quality standards.

Can you help me choose the right hose?

Absolutely. Tap into our technical expertise. Our in-house design and engineering specialists will help you get the right hose for the job. We’ll help you weigh up the options and give you a clear recommendation to solve any hose problems you might have.