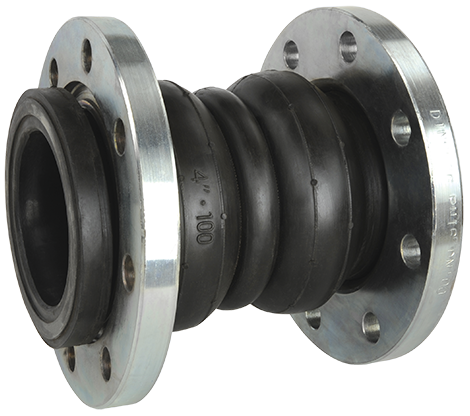

The Beaver Double-Arch Moulded Rubber Expansion Joint enables greater compression, deflection, and elongation than a single-arch joint. It only requires a small force to cause a range of movement that covers axial extension, axial compression, angular movement, lateral deflection, and torsional movement.

This expansion joint is also used to compensate for pipe misalignment, absorb thermal expansion, and dampen noise and vibration in the pipeline. It’s well suited to transporting fluids, slurries, or gases.

Steel reinforcement embedded in grooved rubber ends provides strength under pressure or vacuum. Spherical design distributes internal pressure in all directions, reduces turbulence, and prevents sediment build-up.

Choose from a range of inner tube and outer lining materials to suit your media and site conditions.

Technical specifications

Brand

Model

E22 (PN16)

Size range

Flange drilling

AS2129 Table D, E

ANSI150 and JIS10K available on request

Material specifications

Cover

Reinforcing fabric

Tube and temperature range

Contact us for the following materials:

Hypalon (-62°C to +82°C)

Neoprene (-53°C to +68°C)

NBR (-53°C to +79°C)

Viton (-45°C to +179°C)

PTFE and EPDM (-53°C to +148°C)