On the site visit, he could see that the linkage set-up of the positioners was unreliable, and this was causing the valve to frequently malfunction.

We suggested they redesign the interface between the valve and positioner, and include a fail-safe shut off to make it more reliable.

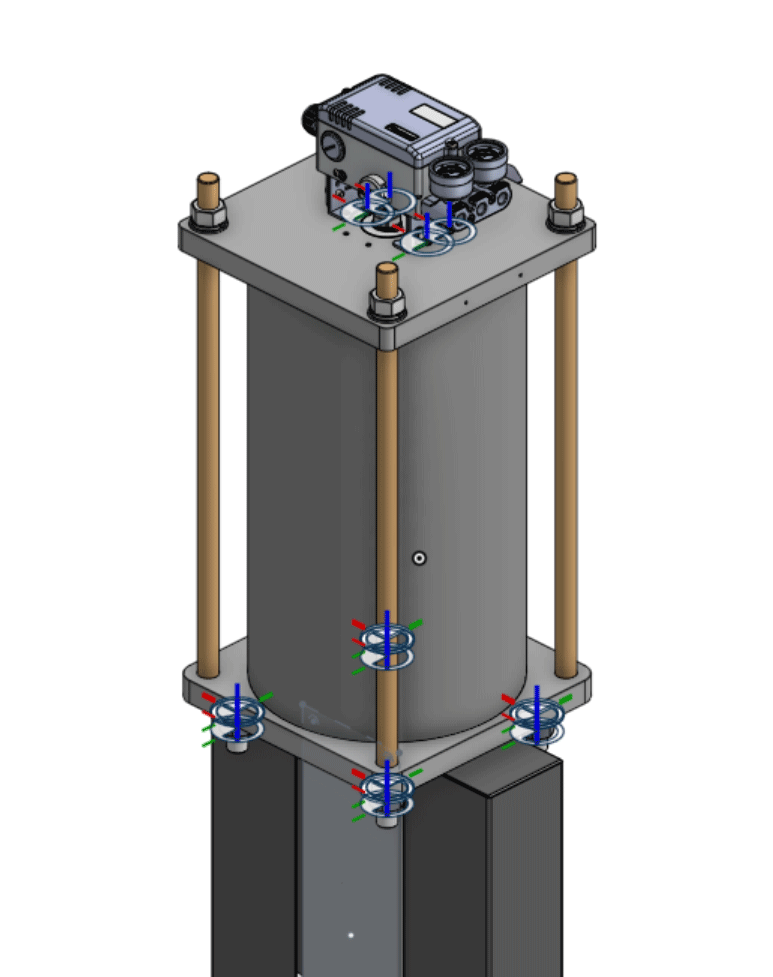

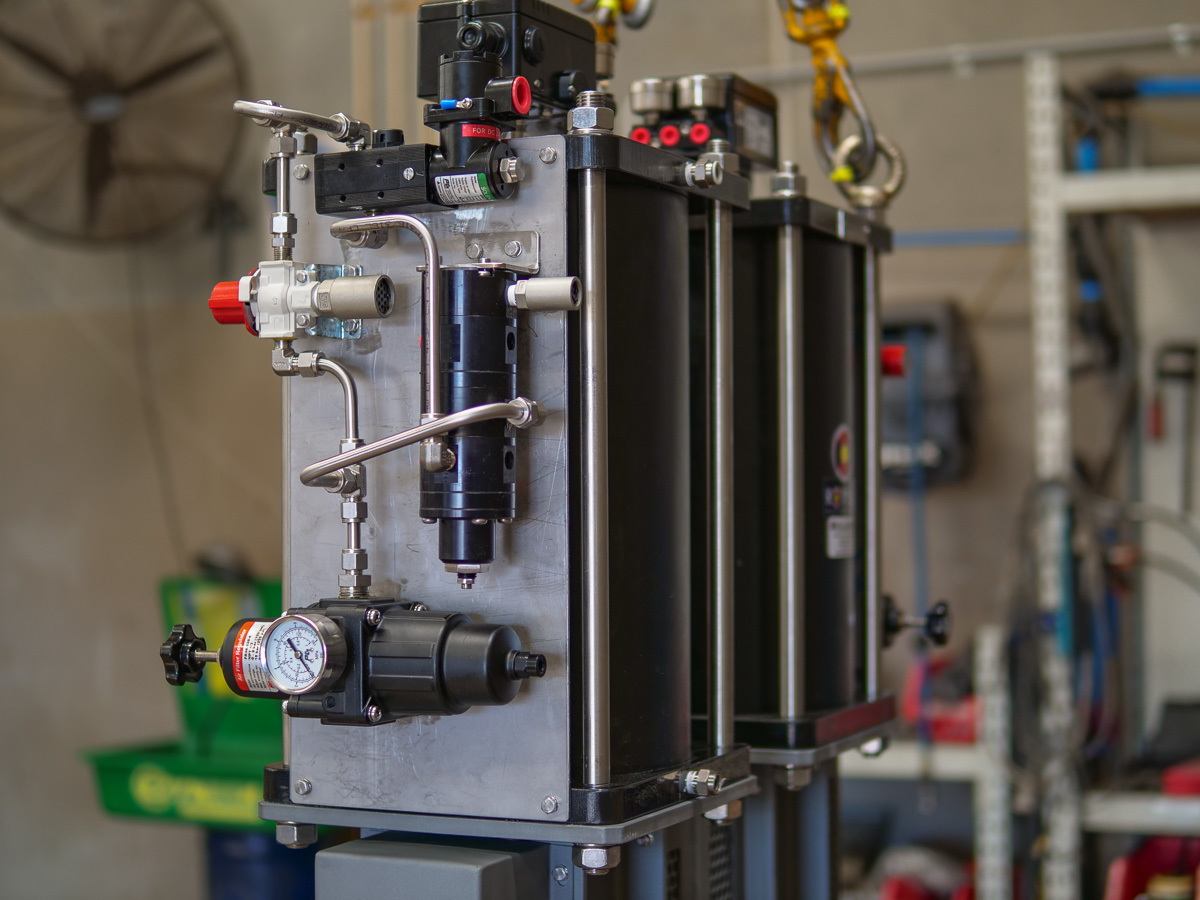

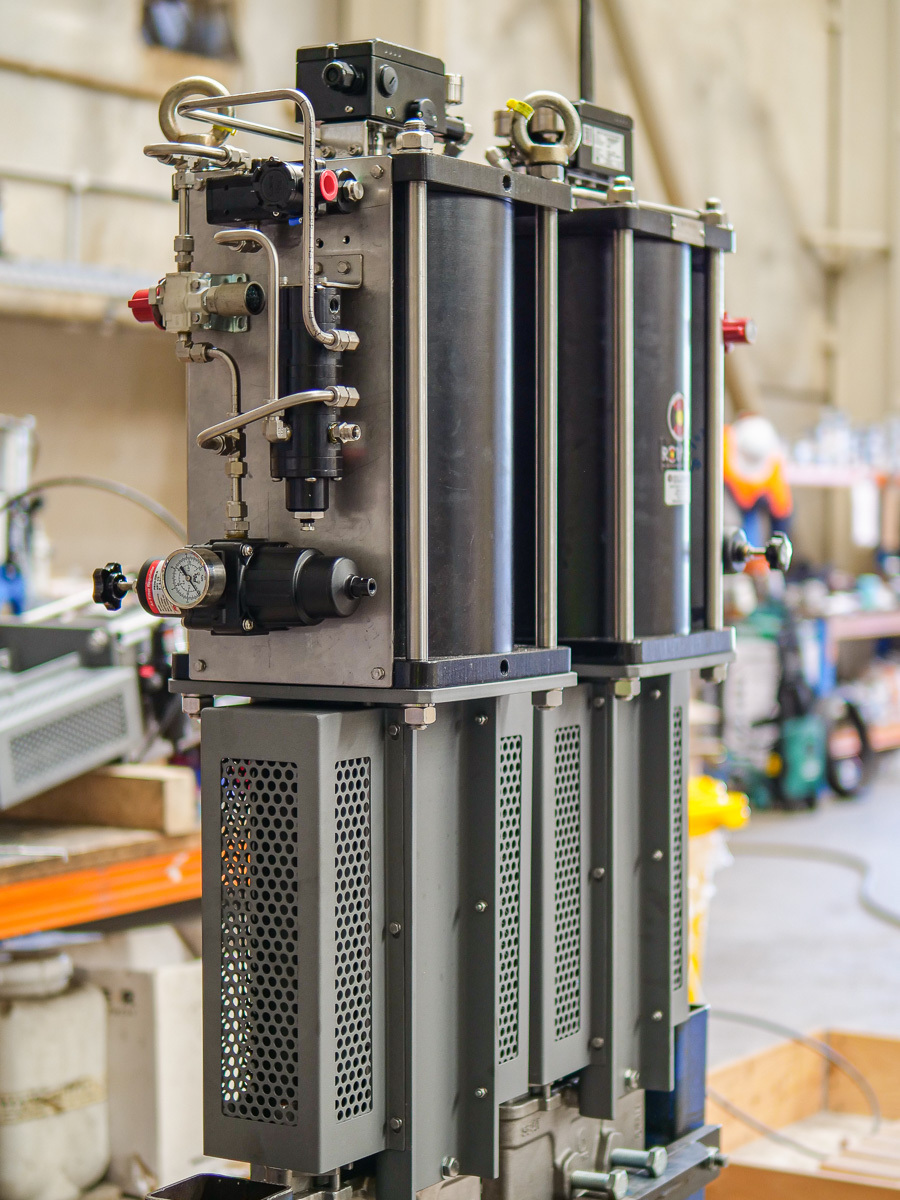

The BHP team agreed with our approach and asked our engineers to come up with a design. We designed a fail-safe system that ensures that the hopper isolates on manual emergency shutdown, loss of power, or a drop in pneumatic pressure.

Then we assembled the valves, fitted with actuators and controls, and fully tested them in our Perth valve workshop. Once they arrived on site, they were ready to install in a plug-and-play state.

It’s a great outcome for Mt Whaleback and we’re pleased we could offer our expertise to help make their site more reliable.