Tired of the same valves jamming, leaking, or failing completely? We help you figure out the causes and fix those problem valves. Get practical advice based on experience and get your plant running smoothly.

Want to fix problem valves for good?

Talk to our team of experts today to find out if a valve performance audit is right for your plant.

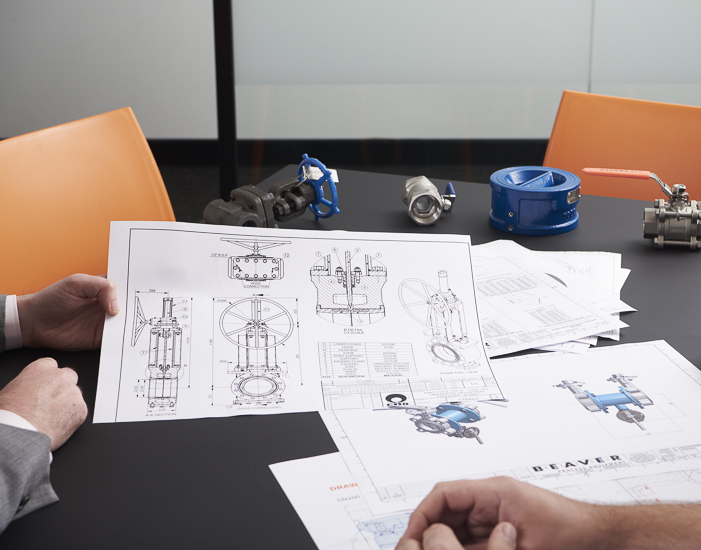

It starts with a plant walkthrough

Show us your problem valves, and we’ll help you get to the bottom of each issue.

We'll walk through the plant with you so you can point out problem areas. Our valve experts will listen to your concerns and discuss the issues and options with you.

We'll identify the causes

Armed with all the information, photos and measurements from the site visit, our expert will prepare your audit report. We’ll look beyond the symptoms and analyse the underlying causes of your valve issues.

Everything gets put into a written report, so you'll know exactly what's behind every issue and how to fix it.

You'll get our analysis and advice in writing

You’ve got a host of valve options. Different valve types and specs. Different materials. Different valve controls. Our report will outline all of the findings and recommendations. We’ll advise you on which upgrades to make—the ones we’d make in your shoes.

We can even provide a complete repair and refurbishment plan, designed to fit into your shutdown schedule.

Helping you make your business case

With our written valve performance audit report in hand, it will be easy to make the business case for your fixes. And we’ll see the job through, providing technical support through install and operation.

By taking informed action, you can put an end to disruptive valve failures. Less ongoing maintenance, less downtime and better productivity all round.

How our valve performance audits work:

Frequently Asked Questions About Valve Audits

What Is A Valve Audit And What Outcomes Can We Expect?

Which Valve Types Are Included In A Valve Audit?

Audits cover knife-gate valves, pinch valves, butterfly valves, ball valves, and automated valve systems, with specifications aligned to our broader valve packages offering.

How Does A Valve Audit Reduce Downtime And Maintenance Costs?

By identifying root causes of sticking, jamming, leakage, and premature wear, a valve audit helps prevent failures before they impact production. Many issues link back to slurry wear behaviour explained in our four types of slurry wear guide.

What’s Included In A Valve Audit Report?

Reports outline valve condition, critical risks, root-cause findings, and recommended repairs or specification changes, aligned with your shutdown and maintenance plan. Recommendations may include upgrades via our valve automation, repair and testing services.

https://www.beaverprocess.com.au/service/valve-automation-repair-testing/

How Do Valve Audits Support Long-Term Pipeline And Plant Performance?

Regular audits ensure valves remain correctly specified for actual slurry conditions, helping prevent misalignment, material mismatch, and avoidable wear. This aligns with our wider slurry piping audit and design principles.

https://www.beaverprocess.com.au/service/slurry-piping-audits/