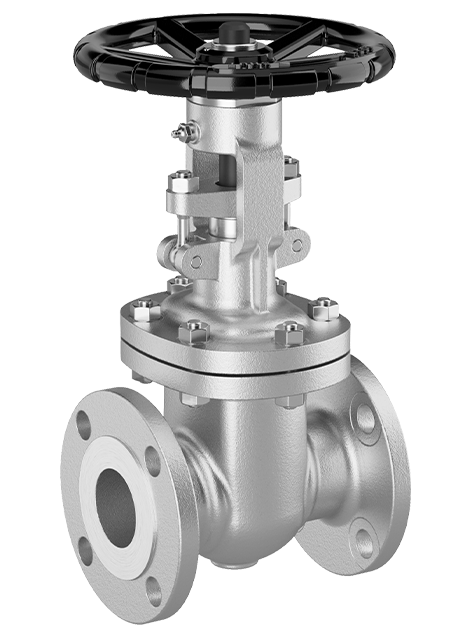

The Beaver API 600 bolted bonnet gate valve is a hard wearing, bi-directional cast steel valve suited for applications where minimal pressure loss and a free bore are required. It is often used as a stop or isolating valve.

The valve is design so that when it’s fully open there is minimal obstruction of flow and low pressure drop. A solid, flexible gate is guided to the seats to create a tight seal. The gate’s flexibility means it’s well suited to applications where line loads or thermal expansion could distort the valve’s seat face.

The seat ring is made with corrosion-resistant cast steel and designed to reduce turbulence in the pipe. There are no cavities in the seat to cause build-up or sticking.

This Beaver API600 bolted bonnet gate valve is manufactured according to API 600 standards.

Technical specifications

Brand

Model

G32 (Class 300)

G33 (Class 600)

Size range

Class 300: DN40–900 (1½–36”)

Class 600: DN50–750 (1½–30”)

Pressure class

End connections

End flange: ASME B16.5

Buttweld: ASME B16.25

Technical specifications

Body, bonnet, yoke, gland flange

A352 LCC

A217 WC6

A217 WC9

A217 C5

A217 C12

A351 CF8M

Gate

A352 LCC + 316 SS

A217 WC9 + 13CR

A217 C5 + 13 CR

A217 C12 + 13 CR

A315 CF8M

Seat ring

A182 F11

A182 F22

A182 F5

A182 F9

A182 F316 all with Stellite

Handwheel

Stem

A182 F316

Backseat bushing, packing gland

A276 316

Yoke cap, handwheel nut, gland eyebolt pin

A276 316

Bonnet bolt, gland eyebolt, yoke bolt

A320 L7

A193 B16

A193 B8

Bonnet nut, gland adjustment nut, yoke nut

A194 4

A194 8