What’s the best way to measure a hose or pipe bend? We get asked this question by our customers all the time. In this article, we share the four key calculations to get the right elbow for your slurry piping system.

The measurements you’ll need to get the right bend ordered are:

- Hose or pipe internal diameter (ID)

- Bend angle

- Centre line radius (CLR)

- Centre to end lines (CTE) x 2

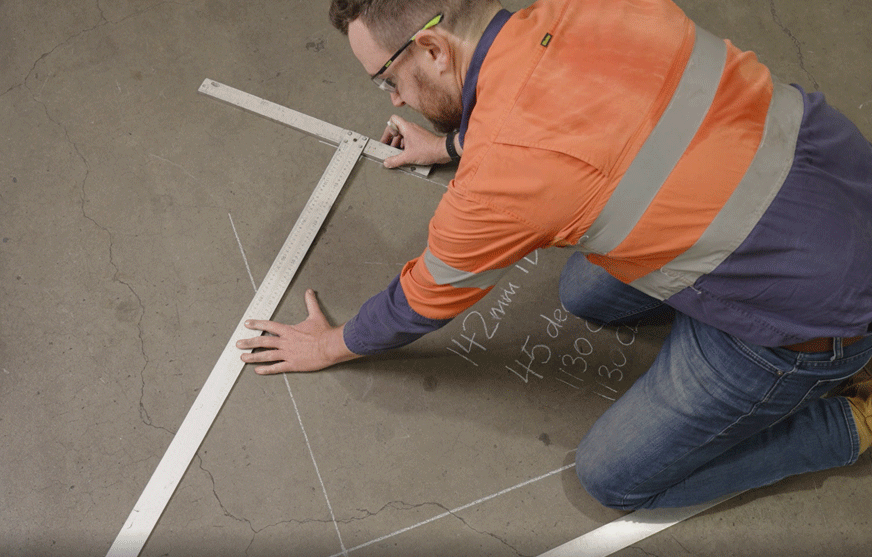

What you’ll need

- Measuring tape

- Straight ruler

- Pencil or chalk

- Protractor

- Pipe or hose bend

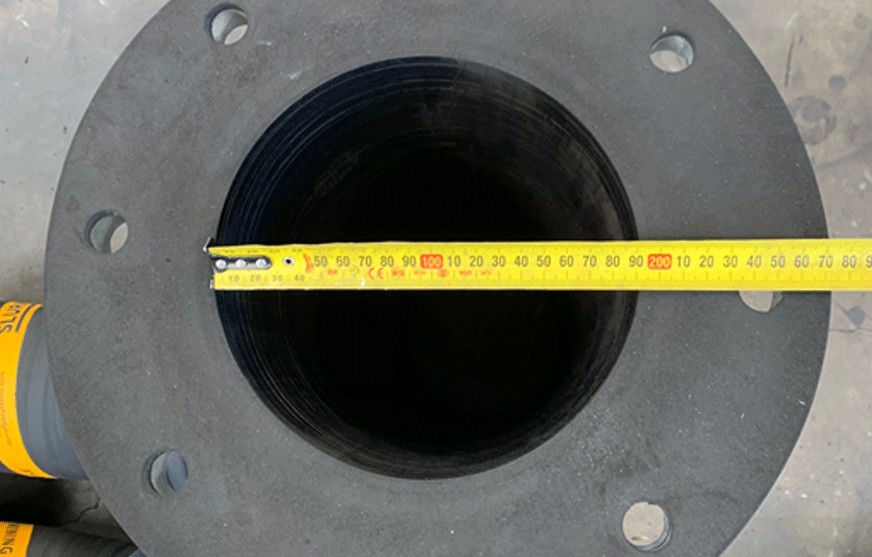

1. Measure the internal diameter (ID)

Use the measuring tape to measure the ID of the hose. If the hose is connected, measure the outer diameter and work back to a possible ID. This can be done by checking the adjoining steel pipe outside diameter, minus the pipe wall thickness and wear liner thickness.

When measuring the diameter on a round object, swivel the tape measure up and down to ensure you’re recording the longest dimension.

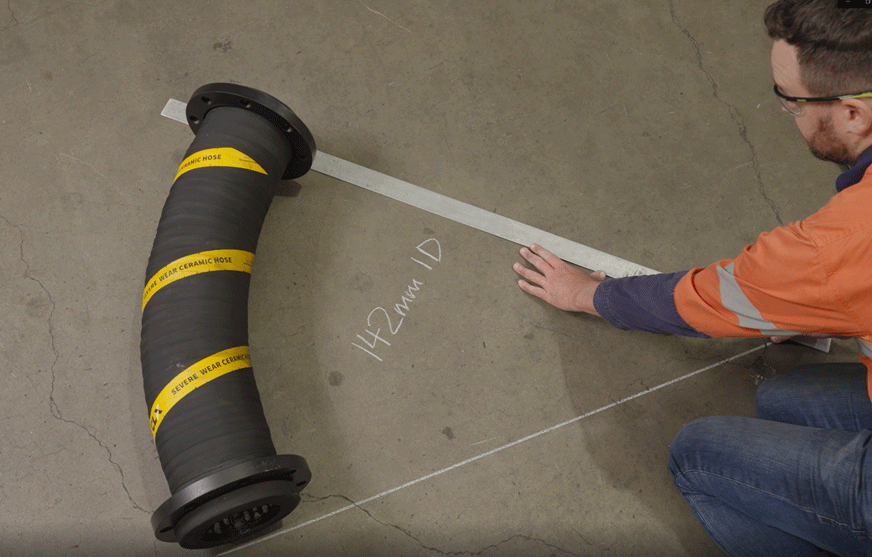

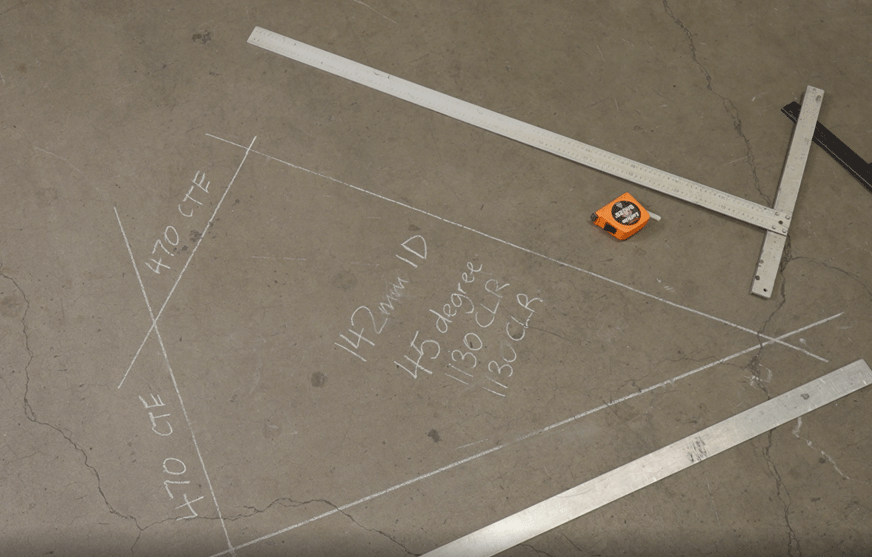

2. Measure the bend angle

Draw a straight, horizontal line from the outside edge of one end of the hose across to where the bend ends. Draw a vertical line at the other end of the pipe to create a centre line. Then use your protractor to measure the angle of the bend.

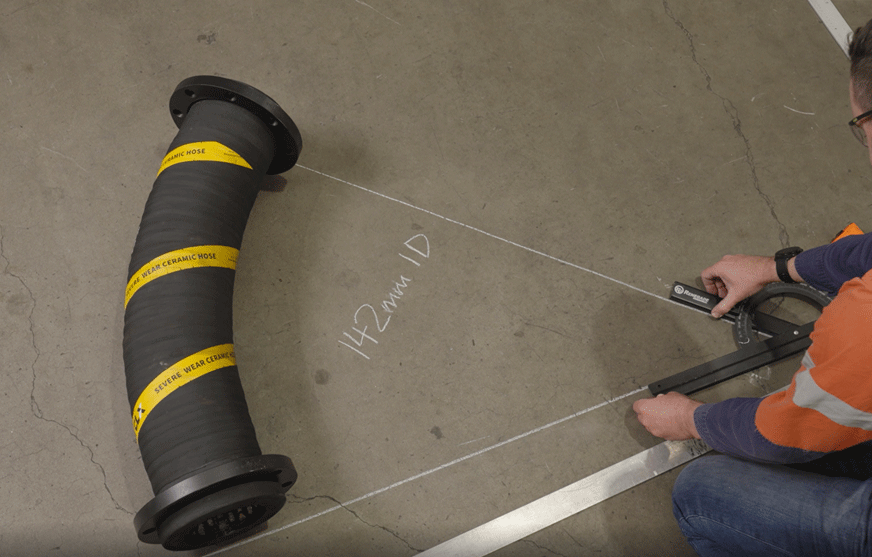

3. Measure the centre line radius (CLR)

The CLR is the measurement from the centre line of the hose (curvature) to the point where both ends meet. To get this measurement, mark the internal radius of one end of the bend and measure to the centre line. Then do the same for the other end.

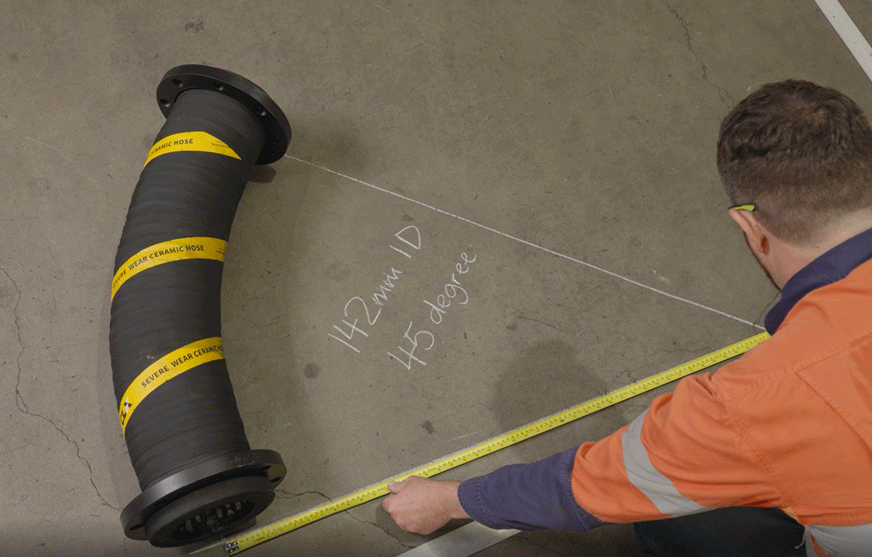

4. Measure the centre to end (CTE) lengths

The CTE lengths are the two measurements from the centre of the bends to the ends of the bend. This includes the tangent lengths (the straight lengths on the end of steel or rigid bends).

You’ll find it easier to move the bend out of the way to take this measurement. You’ll also need your protractor.

To measure this, draw a straight line from the CLR marking at the end of the pipe to the middle of the bend. Then do the same with the other end. Measure the two lengths from the CLR markings to the point where they intersect.

That’s it. Job done!

Sometimes it’s not perfect

At times it’s impossible to measure rigid bends. This can be because there’s no accurate drawing, it’s difficult to access, or there aren’t any reference points to calculate the bend angle.

In these cases, it’s worth looking at mining hose rather than a rigid bend, as its flexibility allows for some tolerance if the measurements aren’t 100% accurate.

If you do have a tricky bend that you need to re-measure every time it needs replacing, check with your supplier if they can create a re-order number for it.

Measure once and you’re done

The last thing you want on shutdown day is a bend that doesn’t fit. Follow these simple steps and you’ll get you the right measurement the first time.