The human skeleton is made up of rigid and flexible elements to give structure and movement.

The same applies for well-built pipelines.

There’s a common misconception that the best pipelines are built entirely from rigid steel piping. While it provides the ‘bones’ of the pipeline, you need flexible elements to accommodate movement.

Without it, you could be facing chronic leaks or catastrophic failure.

Movement kills pipelines

Let’s go back to our skeleton.

Rigid steel in a pipeline is the ‘bones’ – it provides the structural support, shape, and alignment of the pipeline.

But like a skeleton, it also needs to move.

The problem with a completely rigid pipeline design is that it doesn’t allow for movement.

There are five common causes of movement:

- Thermal expansion/contraction: pipelines expand and contract with fluctuations in ambient or fluid temperature. It’s often only millimetres but it’s enough to crack rigid pipework

- Vibration from pumps and other equipment: undetected mechanical issues can increase vibration and stress on both the pump and the connected piping

- Fluid flow: a change in direction (such as a tee or tight bend) or a partially opened valve can cause sudden changes in flow rate which leads to hammer or vibration.

- External forces: things like seismic activity, wind or human disturbance

- Cavitation: this is caused by a pressure drop in the pipeline and can create high frequency vibrations.

All this movement can cause pipelines to rupture. That’s why you need flexibility.

How to be flexible

There’s an easy way to add flexibility to your pipeline design – use mining hose.

It works because:

- Mining hose handles pump vibration and other movement better than rigid pipe. The hose carcass absorbs and dissipates movement shock, reducing wear and risk of leaks

- It’s durable and wear resistant. The internal layer is built for abrasive slurry applications. The hose exterior can deal with high external temperatures, prolonged UV exposure and movement

- It’s easier to install/remove for maintenance: because it can be compressed, stretched or flexed, it’s easier to do change outs around pumps for servicing

Mining hose is the best option to add flexibility to your pipeline

Where to be flexible

By now the benefits of adding flexibility to your pipeline should be clear.

Now let’s look at where you can introduce it.

Between pipeline spools

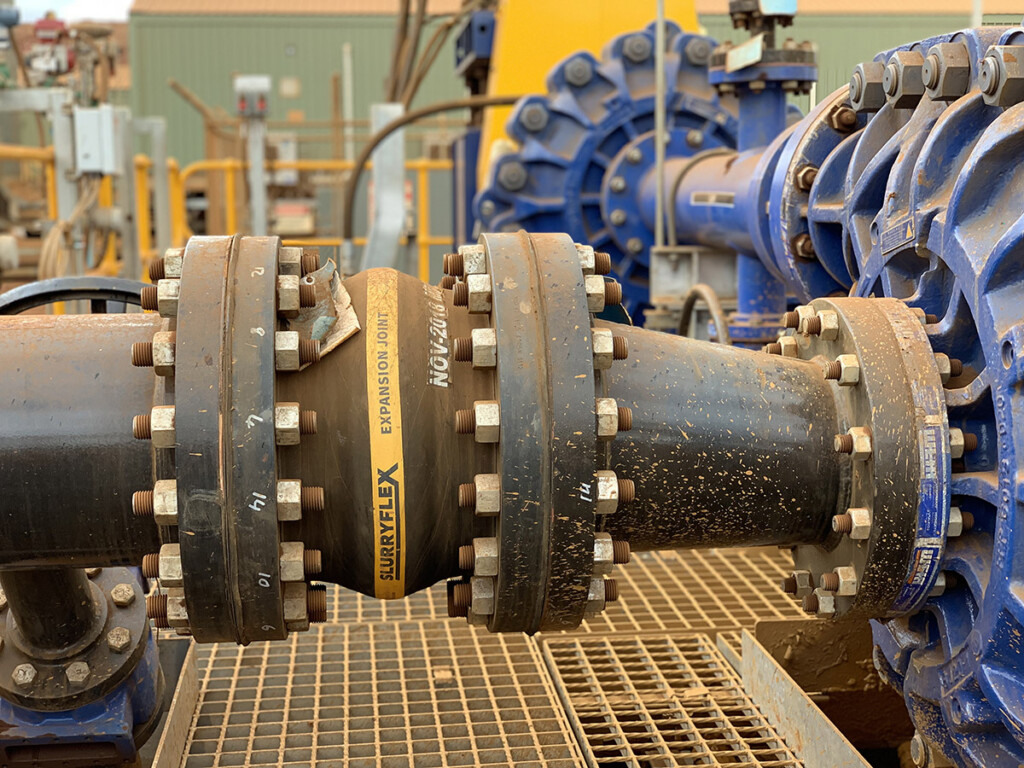

Expansion joints help accommodate movement and prevent rupturing from movement stress.

Mining hose expansion joints work well in pipelines. They provide the space for thermal expansion and contraction between rigid pipe spools.

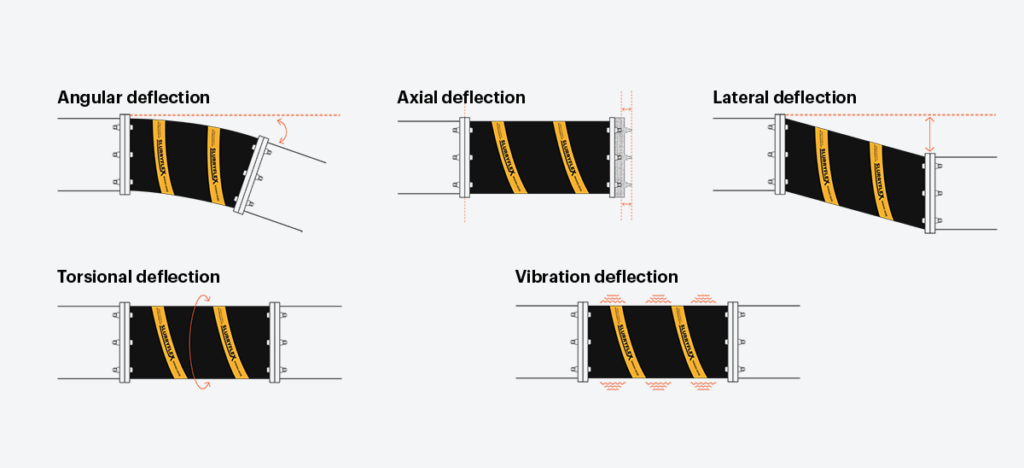

Mining hose expansion joints allow for movement in pipelines.

On bends, undulation & elevation

It not always possible to have a flat pipeline route. Especially on long distance slurry pipelines.

Mining hose is a good option where the pipeline needs to bend or elevate. It’s easier to install because it has greater angular and lateral deflection.

Mining hose has great tolerance for twisting, bending, stretching and compressing.

Around the slurry pumps

Pumps are the heart of any slurry pipeline. They must work at optimal efficiency.

That won’t happen if the connecting pipework is worn and leaking.

Accelerated wear and leaking connecting pipework is typically caused by pipe misalignment from:

- Pump vibration: the constant vibration from pumps causes rigid pipe to move. Over time this will lead to leaks or a more serious rupture.

- Poor installation: if rigid pipework isn’t bolted up or coupled correctly after pump servicing, it will wear and leak. That adds to your maintenance time – and bottom line.

This is where mining hose is a better option. The hose carcass absorbs and deflects vibration from the pump better than rigid pipe. That reduces the risk of misalignment.

Mining hose is also easier to remove and re-install. It’s a big plus for the maintenance team when they’re servicing the pumps or diagnosing pump problems.

Crossings

You’re not limited to rigid piping for under road or rail crossings.

In fact, having flexibility in these areas is beneficial.

Mining hose is a good alternative to rigid piping under crossings because it can accommodate movement and vibration from heavy equipment. The flexibility mean it can bend, stretch or compress, making it easier to install and maintain.

Mining hose can withstand movement and vibration under road or rail crossings.

Flexibility pays off

When it comes to pipelines, you need to be both rigid and flexible.

Mining hose is a good option as it withstands the rigors of slurry service while ensuring there’s flexibility where you need it.

Having both elements creates a system that is both structurally sound and able to accommodate the movement and stresses that occur during normal operation.

Get practical recommendations for your pipeline

Reach out to setup a call with a pipeline specialist. We'll give you clear recommendations and advice to help you with your piping specification, so you can confidently design a pipeline that lasts.

"*" indicates required fields