Ma’aden Barrick Copper Mine – Slurryflex CLX for Ball Mill Feedline

In 2019, the reliability foreman at Ma’aden Barrick Copper Company in Saudi Arabia contacted us about a problem with his ball mill feed line.

The pipework in the feed line was only averaging a lifespan of 3 months. To increase the line’s lifespan, they tried many different products and brands without success.

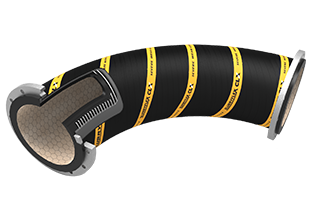

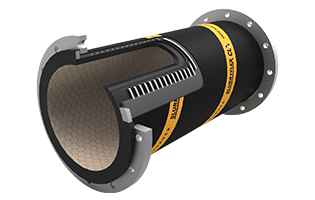

We recommended they try a pre-formed Slurryflex CLX mining hose. The ceramic tile liner gives better wear in severe applications, and the rubber hose provides excellent flexibility and vibration absorption.

The new DN400 mining hose was manufactured in our Brisbane warehouse and then shipped to Saudi Arabia for installation. It has lasted twice as long as the previous hose, with minimal wear. This allows the team to reach the next scheduled shutdown without needing emergency repairs and bandaging.

Client

Ma'aden Client Logo

Year 2019

Project size $0.1M

Location Saudi Arabia

Related content

Slurryflex CLX XC-Series Pre-Formed Bend Ceramic Hose

A ceramic-lined rubber mining hose manufactured in a custom-specified shape for severe slurry applications.

Slurryflex CLX XA-Series Hard-Wall Ceramic Hose

A ceramic-lined rubber mining hose with a hard wall for severe slurry applications.

Slurryflex CLX XE-Series Y-Piece/Lateral/Tee Ceramic Hose

A ceramic-lined rubber mining hose used to connect one pipeline to two others and vice versa in highly severe slurry applications.

We're here to help

Got questions? Need advice? Tap into our experience and get specialist advice from our friendly team.

Slurry piping audits

Solve slurry piping maintenance problems for good. No more leaking pipes, no more unplanned shutdowns.