Selecting the right mining hose for the job can be confusing. In this article, we cover nine common types of mining hose and their typical applications to help you make the right choice for your site—and there’s a handy reference guide at the end.

We discuss:

- Hard-wall suction hose

- Soft-wall discharge hose

- Pre-formed bend hose

- Super flexible mining hose

- Eccentric/concentric reducer hose

- Y-piece mining hose

- Hard-wall dredge hose with floats

- Self-floating dredge hose

- Trunnion or ladder hose

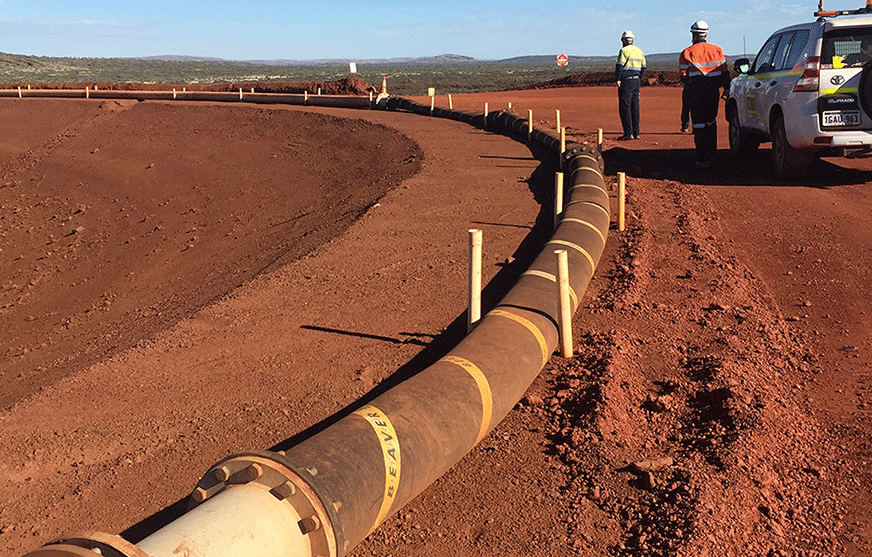

1. Hard-wall suction hose

Hard-wall suction hose is a flexible, straight length rubber mining hose. It has a high-tensile steel wire helix to ensure the hose isn’t sucked flat in vacuum applications. The hose also has a polyester fabric reinforcement to handle high internal pressures.

This type of hose is often used for the pumping and transfer of abrasive slurry under pressure or vacuum. That includes mineral processing, high pressure tailings pipelines, gravel transfer, dewatering, and general material handling.

The hose has excellent tear resistance and tensile strength properties. It also has high abrasion resistance properties and typically operates in temperatures ranging from -30°C to +75°C. There are also different liner options such as synthetic rubber (for high temperature or acidic slurry) or ceramic tiles (for severe service).

Hard wall suction hose has a minimum bend radius of 6-8D. For a more flexible option, consider a pre-formed bend or a super flexible mining hose.

Hard-wall suction hose

2. Soft-wall discharge hose

Soft-wall discharge hose (also known as ‘lay flat’ type hose) is like hard-wall mining hose but for discharge applications only.

The main design difference between the two is that soft-wall hose doesn’t have a rigid wire helix. Instead of this, it has a spring wire reinforcing layer. This makes the hose more flexible when not under pressure, so it’s easier to move from location to location.

It is often used to transport slurry, water, sand, and gravel in mineral processing plants on discharge and tailings lines. It is also suitable for chemical, acid, and hydrocarbon transfer.

Despite the flexibility of soft-wall hose, it has a minimum bend radius of 10D, so it’s best for installation on straight or sweeping bends.

Soft-wall discharge hose

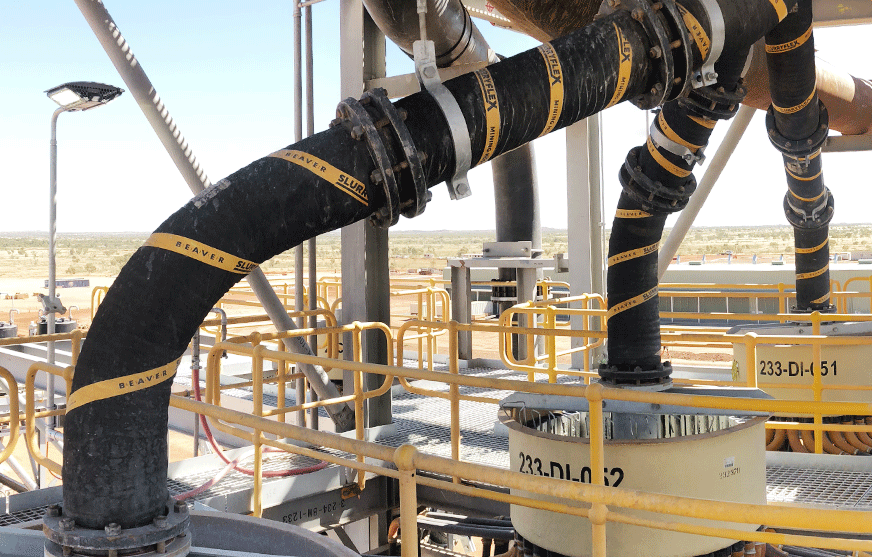

3. Pre-formed bend hose

If you need a hose with a specific angle or bend radius of less than 5D, then pre-formed bend hose is the way to go. It has the same properties as conventional mining hose but is manufactured as a pre-formed bend to your specified angle and radius.

Depending on factors like the hose diameter and materials, it can be manufactured with bends down to a minimum bend radius of 1D. This allows for greater design freedom when arranging complex pipe layouts. To further improve wear life, the wear liner on the elbow’s outer arc can be made at least 50% thicker than the wear liner on the inner arc.

Pre-formed bends are most commonly used in abrasive applications in mineral processing plants, tailings pipelines, dredging, and dewatering.

Pre-formed bend hose

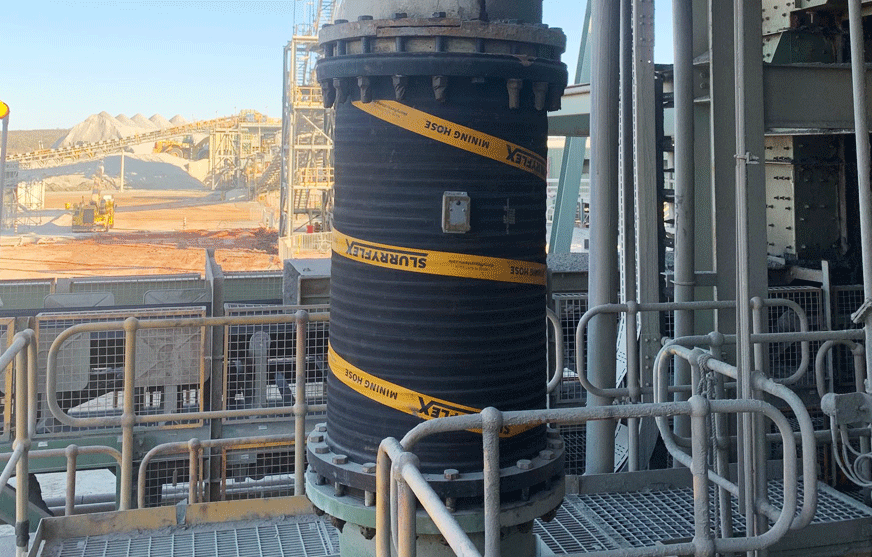

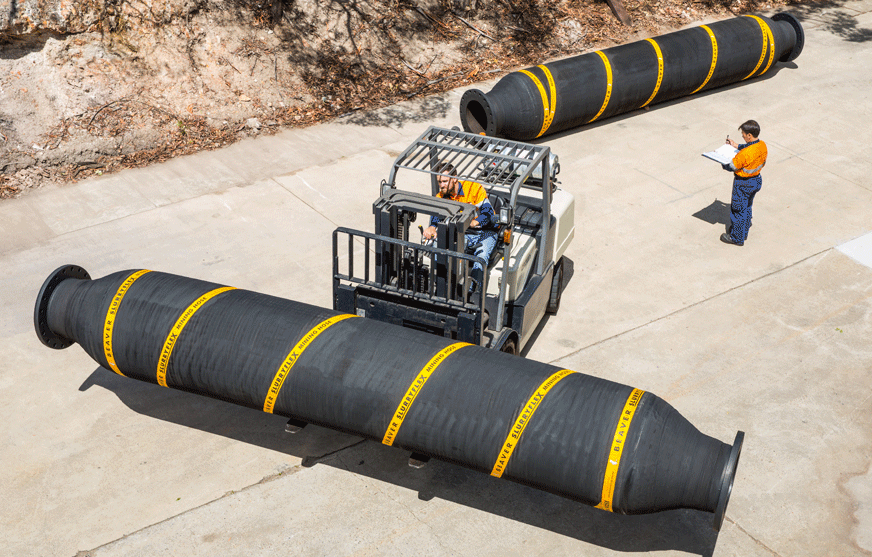

4. Super flexible mining hose

Super flexible mining hose is a specially designed hard-wall mining hose with a smaller minimum bend radius than conventional hose. Depending on factors like the material and nominal diameter, the hose has a bend radius of 4–7D.

You can use it in similar applications to hard-wall and soft-wall mining hose. It’s best suited for tight or complex geometry or where there’s significant pipe misalignment or movement.

Super flexible mining hose

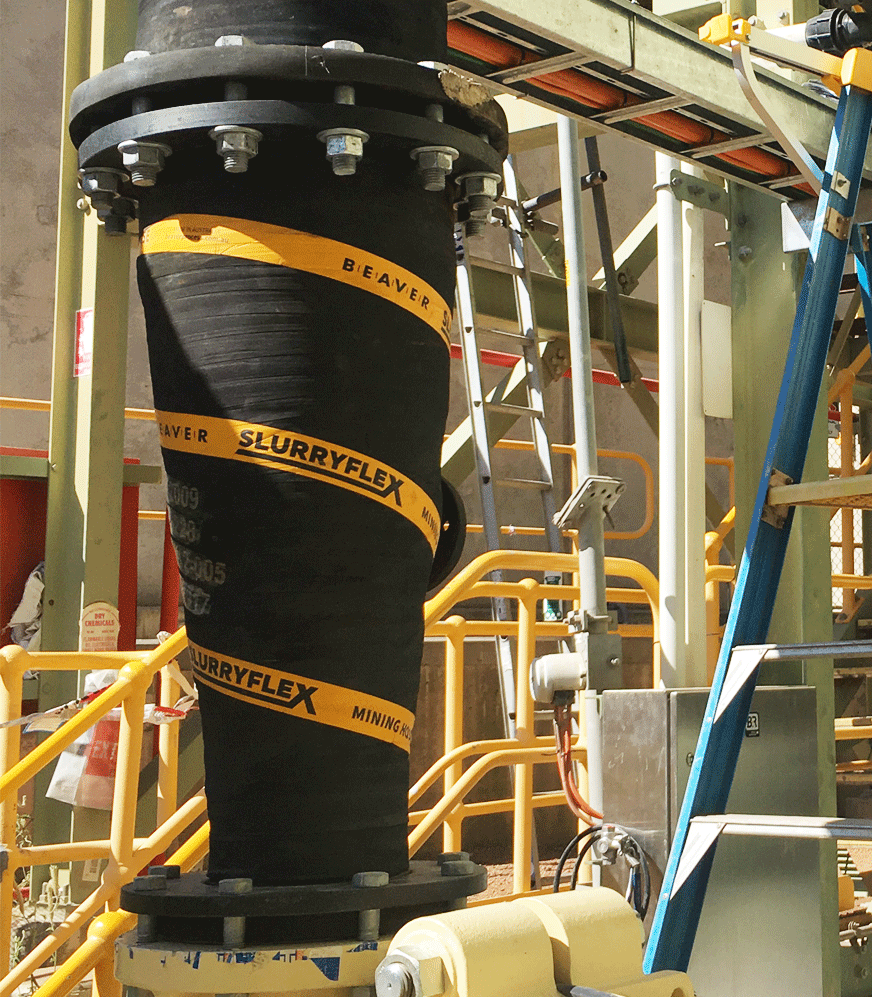

5. Eccentric/concentric reducer hose

Reducer hose is a short-length mining hose with different sized end diameters. Typically, you would use it in slurry pump set-ups to connect larger diameter pipelines to smaller diameter pumps.

The hose is available in two types: eccentric and concentric. Eccentric-type reducers are contoured so their end diameters are on different axes. Concentric hose ends are on the same axis.

Reducer hose is customisable to meet most specifications including size, flange, and liner type.

Eccentric/Concentric Reducer Hose

6. Y-piece mining hose

Shaped like a ‘Y’, Y-piece mining hose connects one pipeline to two other pipelines to simplify the system by reducing the total number of hoses. It has some flexibility but is usually manufactured as a straight-line pipe.

Y-piece hose is often used with a suction pump to divert material into two different hoses, or to combine material from two hoses into one. You can use it with most abrasive materials, such as abrasive slurries, sand, and gravel.

Y-piece mining hose

7. Hard-wall dredge hose

Hard-wall dredge hose is specially designed for dredging applications. It can handle highly abrasive dredging fluids and has increased reinforcing against external punctures, cutting, or abrasions.

Its hard-wall construction makes it ideal for suction applications. For dredging, you can use it with poly floats (floats that fit to your hose’s outside diameter) to prevent snagging and other hazards. The floats are an optional extra and are fitted separately.

Hard-wall dredge hose

8. Self-floating dredge hose

Unlike hard-wall dredge hose, self-floating dredge hose has built-in high-density foam. This makes it an ideal choice for most dredging applications as it doesn’t need additional floats.

It can be reinforced with wire for suction applications or soft-walled for discharge. The soft-wall design is more flexible and helps prevent flexural stresses, such as kinking when hoses are located close to the dredge unit.

Self-floating dredge hose

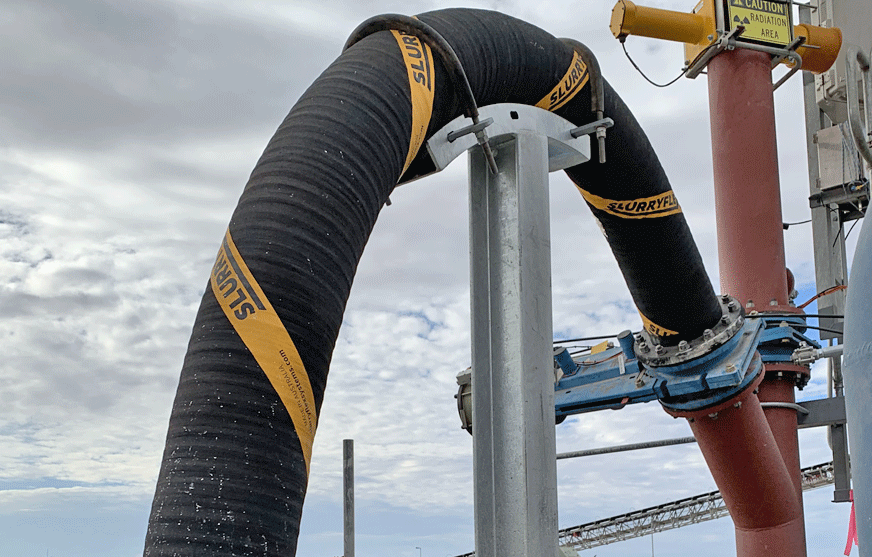

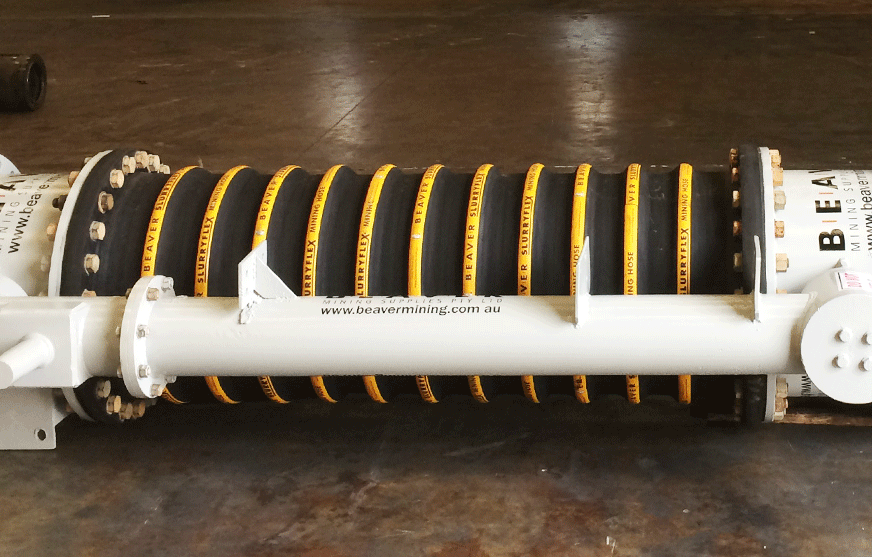

9. Trunnion or ladder hose

Instead of a helix-shaped wire like other suction hoses, trunnion (or ladder) hose has steel rings. This gives it maximum flexibility under vacuum conditions and caters for high loads upon flexing.

Trunnion hose is commonly used for cutter dredging as it can handle highly abrasive fluids, such as freshly cut dredged fluid with undissolved sediment. The extra reinforcement also gives added resistance to external cuts and abrasions.

Trunnion hose is suitable for discharge applications as well.

Trunnion or ladder hose

Mining hose for every application

There are lots of options when selecting mining hose for your site’s requirements. You have the choice of a variety of specifications such as wear liners, reinforcements, size, application, and connection types.

If you aren’t sure which mining hose to select for your application, give us a call. We’ll help you choose the right option and ensure it’s the right hose for the job.

Reference Guide: 9 Mining Hose Types

| Hose type | General properties | Applications | Suction/Discharge |

|---|---|---|---|

| Hard-wall suction hose |

Flexible, straight length rubber mining hose with high tensile steel wire helix.

Excellent tear and abrasion resistance and tensile strength properties. Minimum bend radius of 6–8D. |

Slurry transport in processing plants.

Tailings pipeline. Dewatering. |

Suction or discharge. |

| Soft-wall discharge hose |

Soft reinforcement layer for flexibility and movement between locations.

Suited for installation on straight or sweeping bends. Minimum bend radius of 10D. |

Slurry, water, and gravel transport in mineral processing.

Chemical, acid, and hydrocarbon transfer. Tailings lines. |

Discharge only. |

| Pre-formed bend hose |

Pre-formed bend hose with custom angle and bend radius. Provide durability of normal mining hose. Minimum bend radius of 1D. |

Slurry and water transfer in mineral processing plants.

Tailings pipelines. Dredging Dewatering |

Suction or discharge. |

| Super flexible mining hose |

Super flexible hard-wall mining hose.

Increased flexibility for movement between locations. Ideal for tight locations or complex plant set-ups. Can achieve tight bend radius without kinking. Minimum bend radius of 4–8D. |

Slurry or water transport in mineral processing plants.

Chemical, acid, and hydrocarbon transfer. Tailings pipeline. Dredging Dewatering |

Suction or discharge. |

| Reducer Mining Hose |

Short-length mining hoses with different-sized end diameters.

Commonly used in slurry pump applications to connect larger diameter pipelines to smaller diameter pumps. Available as eccentric or concentric reducer. Customisable to meet most specifications including size, flange and liner type. |

Slurry or water transport in mineral processing plants.

Tailings pipeline. Dredging Dewatering |

Suction or discharge. |

| Y/Lateral/Tee piece mining hose |

Y/Lateral/Tee piece hose to channel pipelines and simplify pipework.

Customisable to meet specific design requirements. |

Slurry transport.

Chemical, acid, and hydrocarbon transfer. |

Suction or discharge. |

| Hard-wall dredge hose |

Designed for dredging applications.

Additional reinforcement to protect against external punctures, cutting or abrasions. Best used with external poly floats to prevent snagging. |

Dredging |

Suction or discharge.

Most commonly used for discharge. |

| Self-floating dredge hose |

Built-in high-density foam to achieve buoyancy.

Can be reinforced with wire for suction applications or soft-walled for discharge. |

Dredging | Suction or discharge. |

| Trunnion hose |

Steel ring reinforcement for maximum flexibility under vacuum and high loads.

Resistant to external cuts and abrasions. Ideal for cutter dredging as resistant to highly abrasive freshly cut dredged fluid. |

Cutter dredging. | Suction or discharge. |