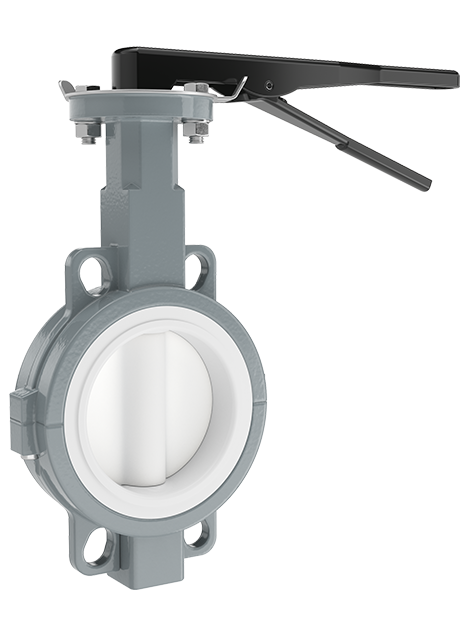

The Beaver F11–F12 butterfly valve has a two-piece body with a concentric design. The stem is centred in the disc and the disc centred in the bore. Such a symmetric design allows for high flow values and minimises pressure drops.

The valve’s distinguishing feature is a PTFE-lined disc complemented by a PTFE seat that covers the entire surface of the body in contact with the media. PTFE protects the valve from corrosion, making it suitable for chemical and petrochemical applications where standard elastomers will likely fail.

This butterfly valve is available with a wafer or lugged body design.

Technical specifications

Brand

Beaver

Model

F11 (Wafer)

F12 (Lugged)

F12 (Lugged)

Size range

DN50–300 (2–12”)

Pressure class

10 bar

End connections

Wafer: AS2129 Table D/E and ANSI 150

Lugged

Lugged

Actuator options

Lever with notch plate

Manual gear operator

Manual gear operator

Material specifications

Body

Cast iron

Ductile iron

Ductile iron

Disc

PTFE-coated stainless steel

SS316

SS316

Stem

SS410 (Wafer)

SS316 (Lugged)

SS316 (Lugged)

Seat

PTFE

O-ring

NBR (Nitrile)