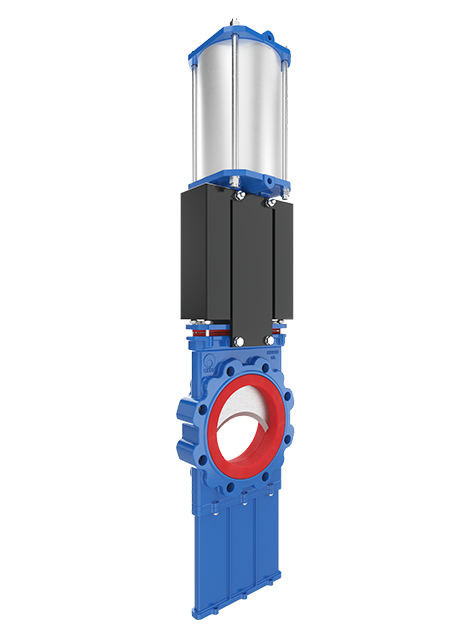

A custom modified version of the GL model, the CMO GLP Slurry Knife Gate Valve uses Abrasiguard sleeves. Abrasiguard is a proprietary polymer manufactured in Australia that improves seal reliability and overall service life. This upgrade makes the valve suitable for more challenging slurry applications.

The ported gate fully aligns with the resilient sleeves in the open position to form a full bore. This ensures unobstructed flow with high flow rates and low pressure drop. The polymer sleeves also compress on the gate through the entire stroke, flushing particles out of the bottom of the valve and creating a bubble-tight seal in the closed position. Because the sleeves completely supporting the gate, the GLP is better suited to non-vertical orientations than other types of knife gate valve.

The CMO GLP Slurry Knife Gate Valve is suitable for transporting highly abrasive slurry and is specified for horizontal installation.

Technical specifications

Brand

Model

Size range

Contact us for bigger sizes

Pressure class

6 bar (DN700–900)

4 bar (DN1000–1500)

End connections

Actuator options

Gear operated

Pneumatic

Hydraulic

Electric

Material specifications

Body

On request: A216WCB carbon steel and stainless steel alloys (AISI 316 Ti, Duplex 254 SMO, Uranus B6, Ni-Resist, Ductile Ni-Resist)

Gate

On request: Duplex SAF 2205 and 2507, stainless Steel 17-4PH, and other materials, coatings, and finishes

Seat and max temperature

Viton (210°C)