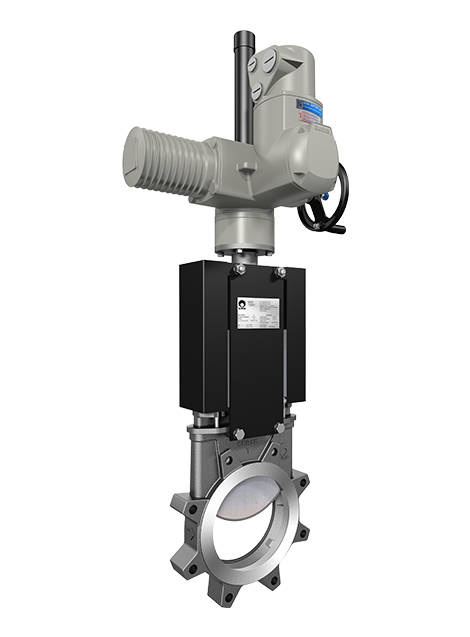

The CMO T Knife Gate Valve is a guillotine valve with a monobloc integral cast body. Interior slides ensure the gate operates efficiently, while wedges promote a tight seal. The valve meets MSS SP-81 and TAPPI TIS 405‐8 standards on face-to-face dimensions for flanged knife gate valves.

The body has a conical shape to create enough space for the gate to push out any lodged solids. This also minimizes the torque required to close the gate after it has been open for long periods.

This valve is designed for unidirectional flow. It also supports up to 30% of the working pressure from the opposite direction thanks to internal slides that protect it from counterpressure.

The CMO T Knife Gate Valve is suitable for clean liquids and liquids with up to 6% solids concentration.

Technical specifications

Brand

Model

Size range

Contact us for bigger sizes

Pressure class

8 bar (DN700–900)

4 bar (DN1000–1200)

End connections

Actuator options

Gear operated

Pneumatic

Hydraulic

Electric

Material specifications

Body

On request: Stainless steel alloys (AISI 316 Ti, Duplex, 254 SMO, Uranus B6)

Gate

Contact us for other materials, coatings, and finishes

Seat and max temperature

Silicone (200°C)

Viton (210°C)

Metal (>250°C)