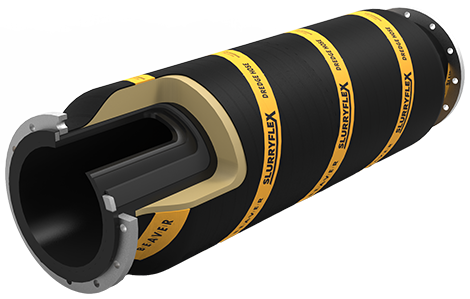

The Slurryflex DG-Series Self-Floating Dredge Hose is similar to the SB-Series Soft-Wall Mining Hose with an additional integral foam casing to allow it to float independently.

This soft-wall hose consists of a slurry wear-resistant rubber inner layer, a soft reinforcement layer to contain internal pressure, and an outer cover that protects from UV, ozone, and external abrasion. This gives it greater flexibility and prevents kinking around bends or close to the dredge.

High-density closed cell foam provides buoyancy without the need for additional floats and also prevents water absorption. The DG self-floating hose is suitable for discharge duty only.

Slurryflex hoses are completely custom made according to your specifications. We manufacture them in Australia from Slurryflex Grade A rubber for long-lasting resistance to abrasion, cutting, tearing, and overall wear. Talk to us about your application and we’ll help you choose the right hose for the job.

Technical specifications

Brand

Model

Hose size

Hose length

Pressure rating

Higher on request

Temperature rating

Buoyancy rating

End connections

Full spigod swivel flange

Custom

Flange types

Safety factor

Extra options

Wear monitoring system (plug-only or push-button)

Material specifications

Inner liner

Slurryflex ASR rubber (for acidic slurry)

Slurryflex HSR rubber (for hydrocarbon-containing slurry)

Slurryflex TSR rubber (for high-temperature slurry)

Slurryflex custom formulation

Reinforcement

Outer cover

End connections

Stainless steel (SS304, SS316)

Exotic alloy